Thank you for participating in our hydrogen Market Survey. Your insights are invaluable in helping us understand current market trends,...

Read MorePowering a sustainable future with Green Ammonia

Our mission is to power the shift to carbon-free industries with green ammonia, the new sustainable energy vector.

About Us

Welcome To NitroPrime

A vision for a sustainable European industry through renewable energies

At NitroPrime we are pioneering the future of sustainable energy by leading the production of green ammonia. Our mission is to leverage the versatility of ammonia and make it a clean, efficient and environmentally friendly solutions that drive the transition to a sustainable future.

Our values

At NitroPrime we value

Trust and partnership

We believe in building strong, transparent relationships with our stakeholders, fostering a culture of mutual respect and collaboration. Trust and partnership are the foundation of our success, ensuring that we work together effectively towards common goals and shared success.

Green Energy only

Our commitment is to use only renewable energy sources in our operations. By focusing exclusively on green energy, we reduce our carbon footprint and contribute to a cleaner, more sustainable future for all.

Smart and Agile

We embrace innovation and flexibility in our operations. Our smart and agile mindset allows us to quickly adapt to changing conditions and seize new opportunities, driving efficiency and staying ahead in a dynamic market.

People and nature first

We prioritize the well-being of our people and the environment in everything we do. Our approach ensures that our business practices are not only beneficial to our team but also respectful of nature, promoting a harmonious balance between industrial progress and ecological preservation.

Our Product

What We Are Selling

Green Ammonia

Certificate of Origine

Fertiliser and other ammonia derivatives

(On demand)

Other ammonia derivative

(on demand)

Our Project

Green Ammonia Plant in the south of Morocco

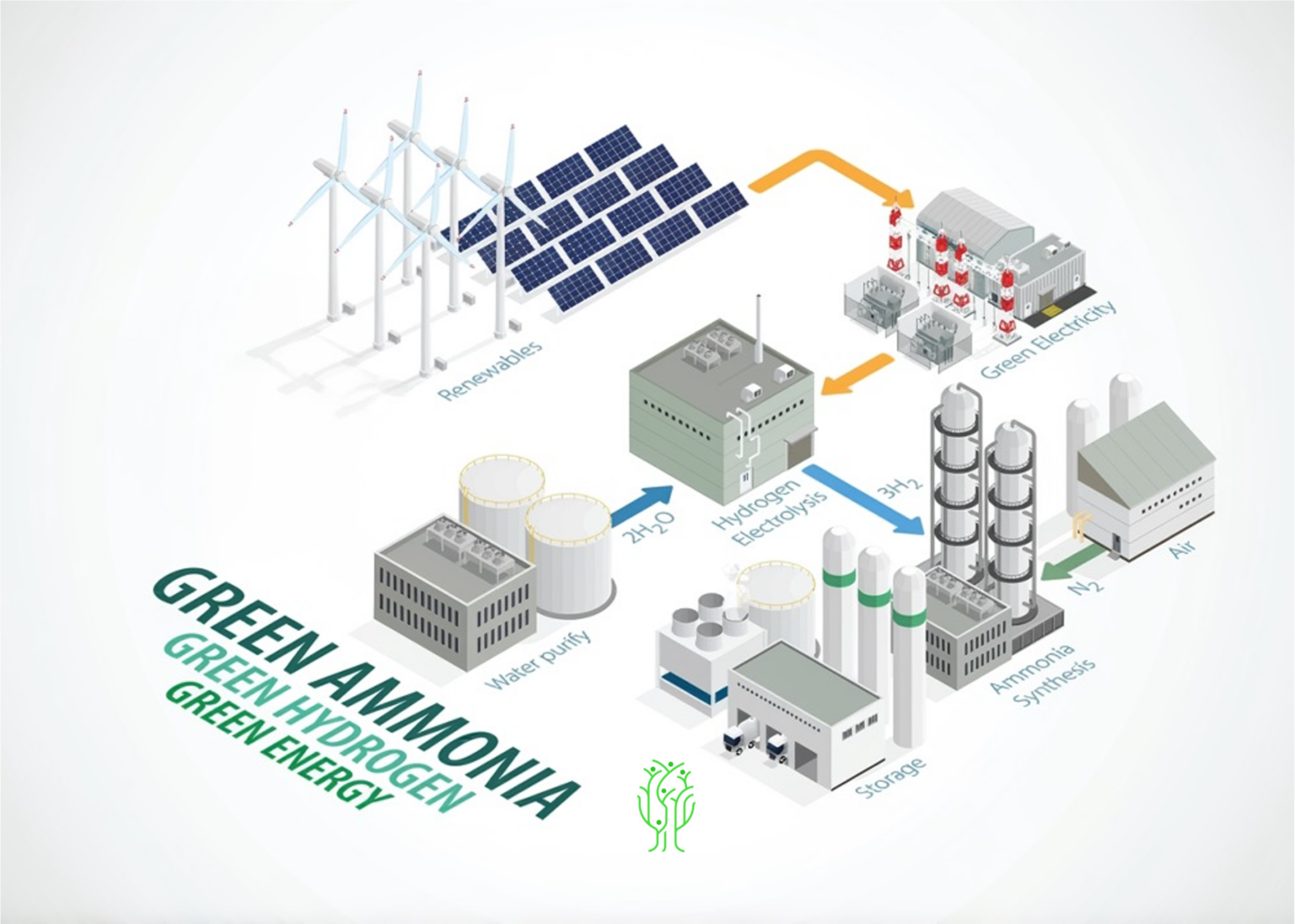

NitroPrime scope will cover the green electricity production (wind/solar mix), the water desalination, the electrolysis and the ammonia loop process, storage and shipment via Moroccan sea infrastructure to Europe.

Green energy production unit

Use renewable sources (wind and solar power) combined with appropriate storage to produce electricity. The electricity production form renewable and energy storage system will be interfaced to the other plant units through dispatching unit.

Water purification unit

This unit aims at purifying water so it met the electrolyse(s) requirements. The station should also consider a water desalination system depending if the water is issued by the Moroccan authorities or retrieved directly from the sea.

Hydrogen Electrolysis unit

This unit consists mainly of electrolyses stack(s) and hydrogen storage system. The produced hydrogen shall met the purity required by the ammonia synthesis loop. Also, a heat retrieving from the electrolyses stacks system may be considered in this unit, which may be used in other units.

Nitrogen separation unit

This unit aims at extracting Nitrogen from the air. The produced Nitrogen purity shall met the level required by the ammonia synthesis loop.

Ammonia synthesis unit

This unit produces the green ammonia, meeting the clients requirements of purity using as input the hydrogen produced by electrolysis and nitrogen extracted from air. The process considered here is Harber-Bosch.

Ammonia Storage unit

This unit main function is the storage and the dispatch of the produced Green Ammonia. The ammonia should be stored according to

Transition to Green ammonia will help us to move to a greener world

Transitioning to green ammonia can help industries reduce their carbon footprints, aligning with global efforts to combat climate change and achieve net-zero targets.

Switch to the fuel of the future

The production capacity of green ammonia and green hydrogen is one of the barrier not allowing to adopt them as an alternative to fossile fuels. Helping us to increase the production capacity is a major contribution to the adoption of green hydrogen and ammonia as the fuel for transports means (buses, trains, ships, etc.) but also fuel for hydrogen dependent industries such as steel manufacturing.

Help to balance Eco system

Ammonia is a critical component in fertilizers. Green ammonia provides a sustainable alternative to conventional ammonia which relies heavily on fossil fuels. This shift will reduce the carbon footprint of agriculture.

Chemical Industry

Green ammonia can be a raw material for producing various chemicals, including methanol, which can lead to more sustainable practices in chemical manufacturing.

Power generation

Ammonia can potentially be used in fuel cells and power generation systems, providing a low-emission alternative to conventional fossil fuels power gen.

News & Blogs

Latest Blogs From Our Vault

Ammonia market survey

Thank you for participating in our Fertilizer Market Survey. Your insights are invaluable in helping us understand current market trends,...

Read MoreOur Project in one page

Europe is engaged in an historical decarbonation shift. The ambition is huge, figures are hard to grasp. To meet this...

Read More